I'll Take 9

I’ll Take 9 was a three week project in which a brand is mismatched with a product, and teams are asked to design a new item from the pair they are given. It was divided into three phases, concept, prototype, and manufacturing. In between phases, teams switched projects with one another. At the end of the project, each team manufactured 9 units of their final product.

Concept - Oakley + Sugar Shaker

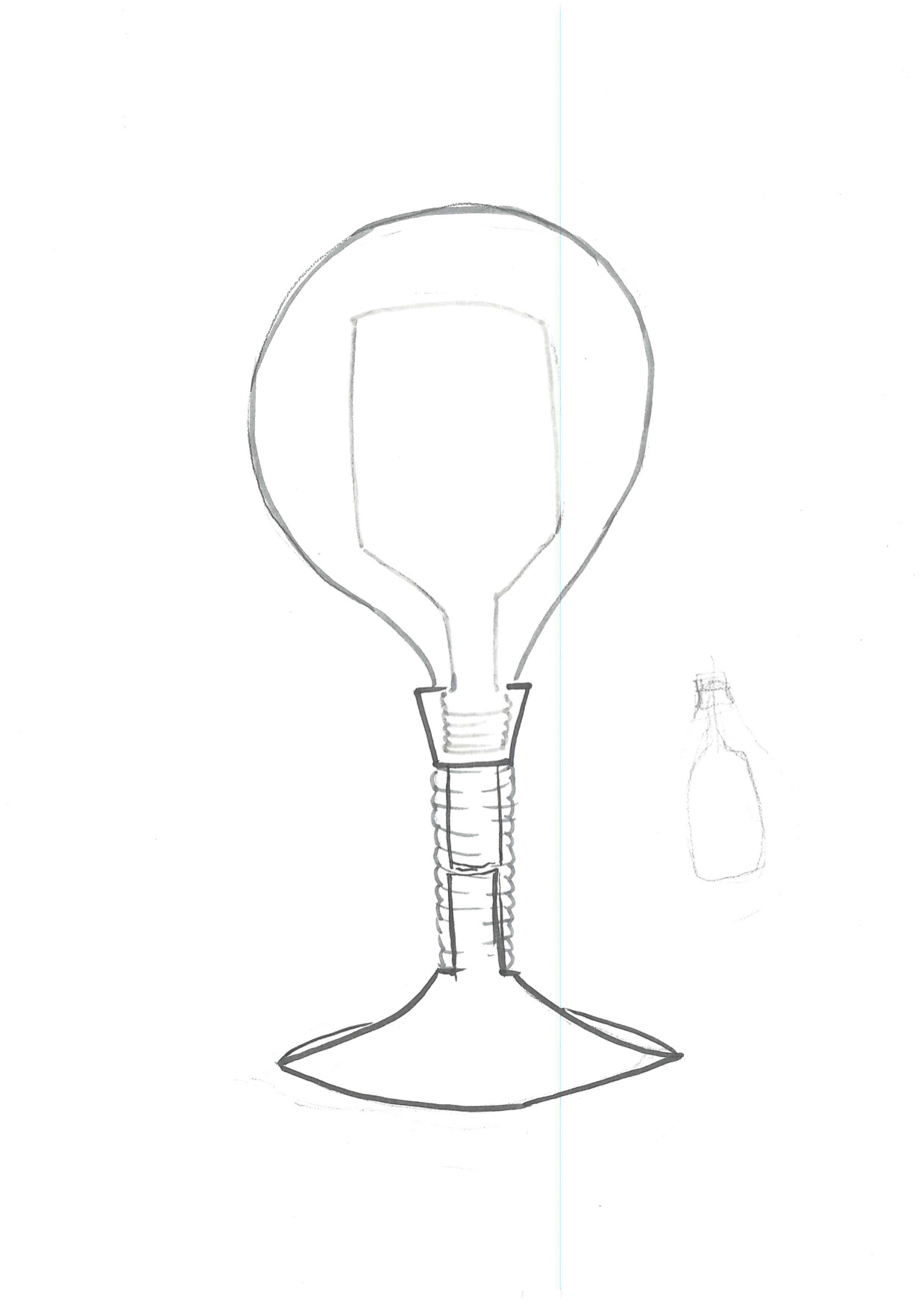

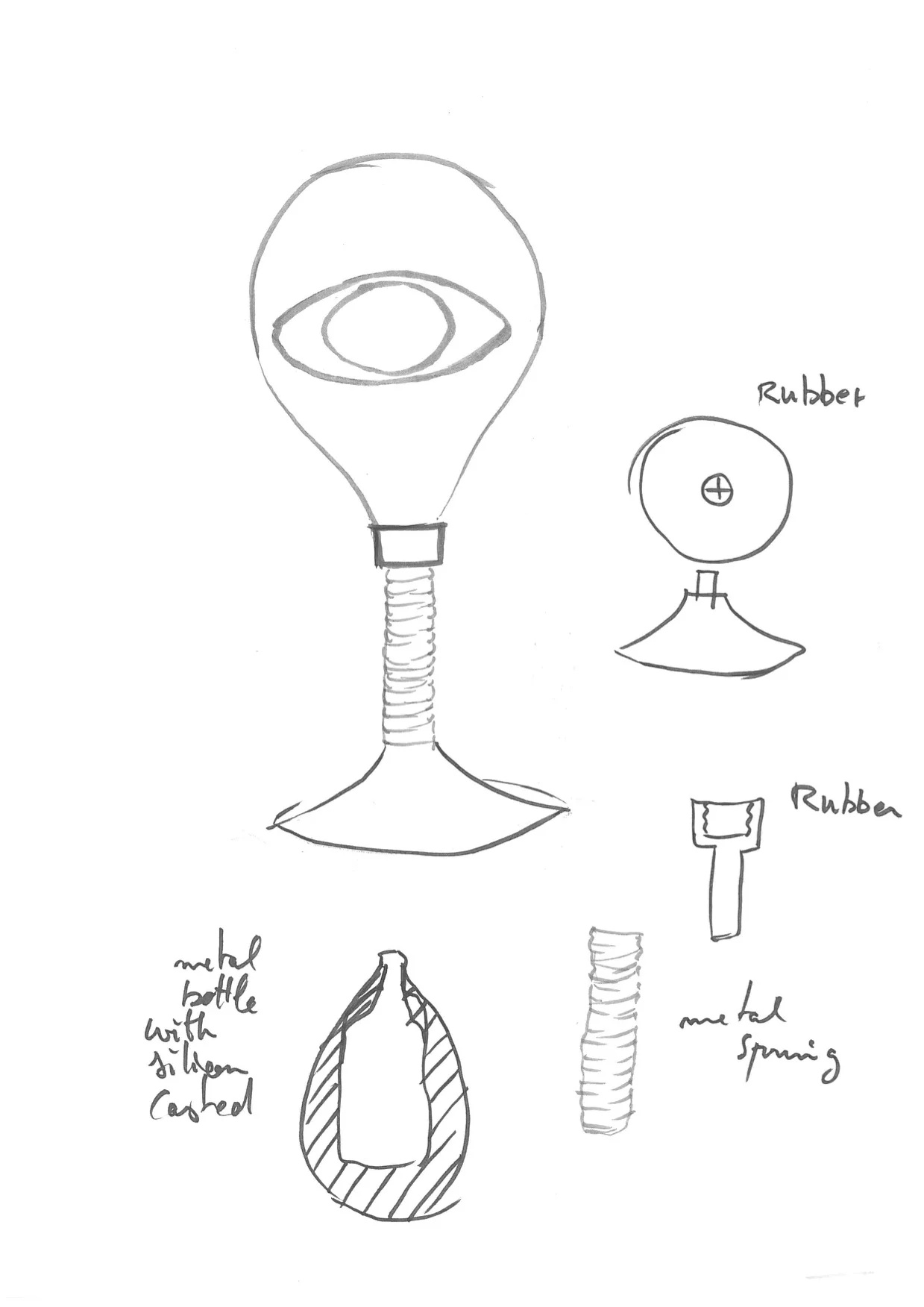

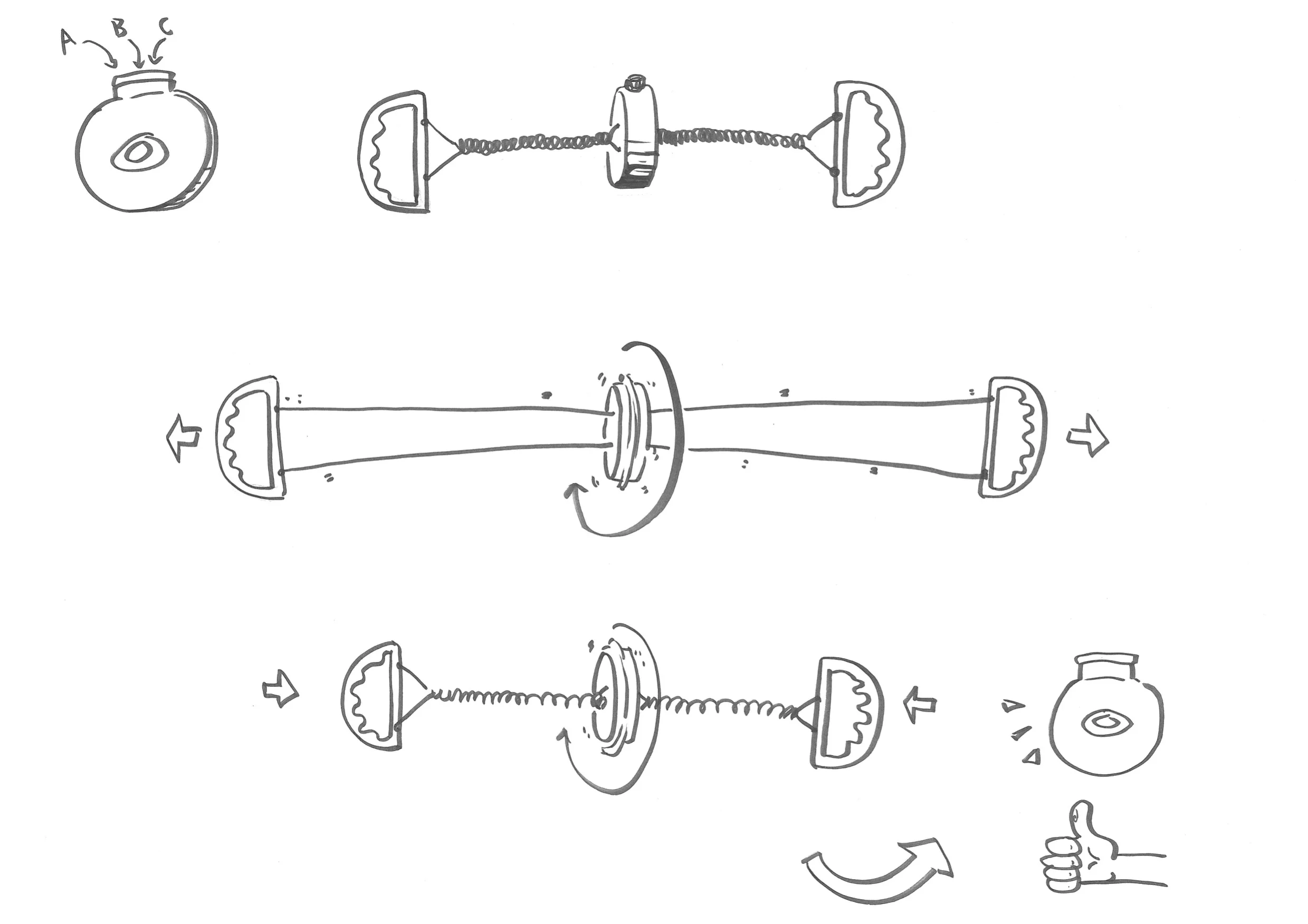

We took note of the bold, extreme sports angle of the Oakley brand, as well as the hyper-masculine, showy persona of the typical Oakley user. We also expanded on the idea of a sugar shaker to products that are more relatable to the Oakley user, such as an energy shaker and cocktail shaker. The first product below is based off of a boxing speed ball and the second is based off of a whirli-gig.

Prototype - Absolut Vodka + Watering Can

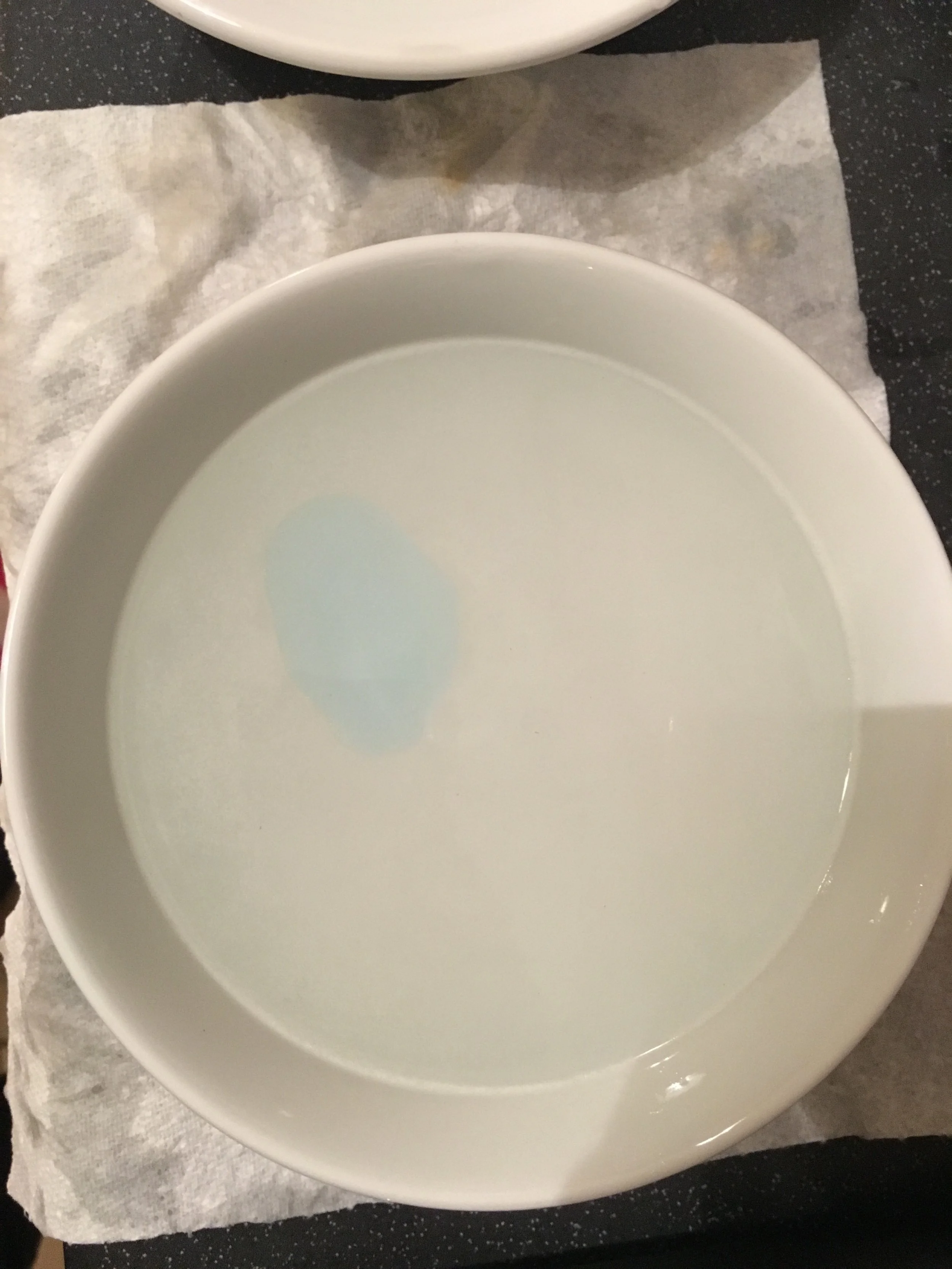

We were given the concept Absolut Secret, a gobstopper candy infused with vodka, with a shot of vodka in the center. We explored several gastronomic routes to infuse vodka into a hard candy and to encapsulate a shot of vodka. We looked at several techniques including freezing, powdered alcohol, and reverse spherification. Our final prototype was made by fusing two hemispherical shells of hard candy together and injecting vodka inside through a small hole using a syringe.

Manufacturing - Dr. Marten + Trivet

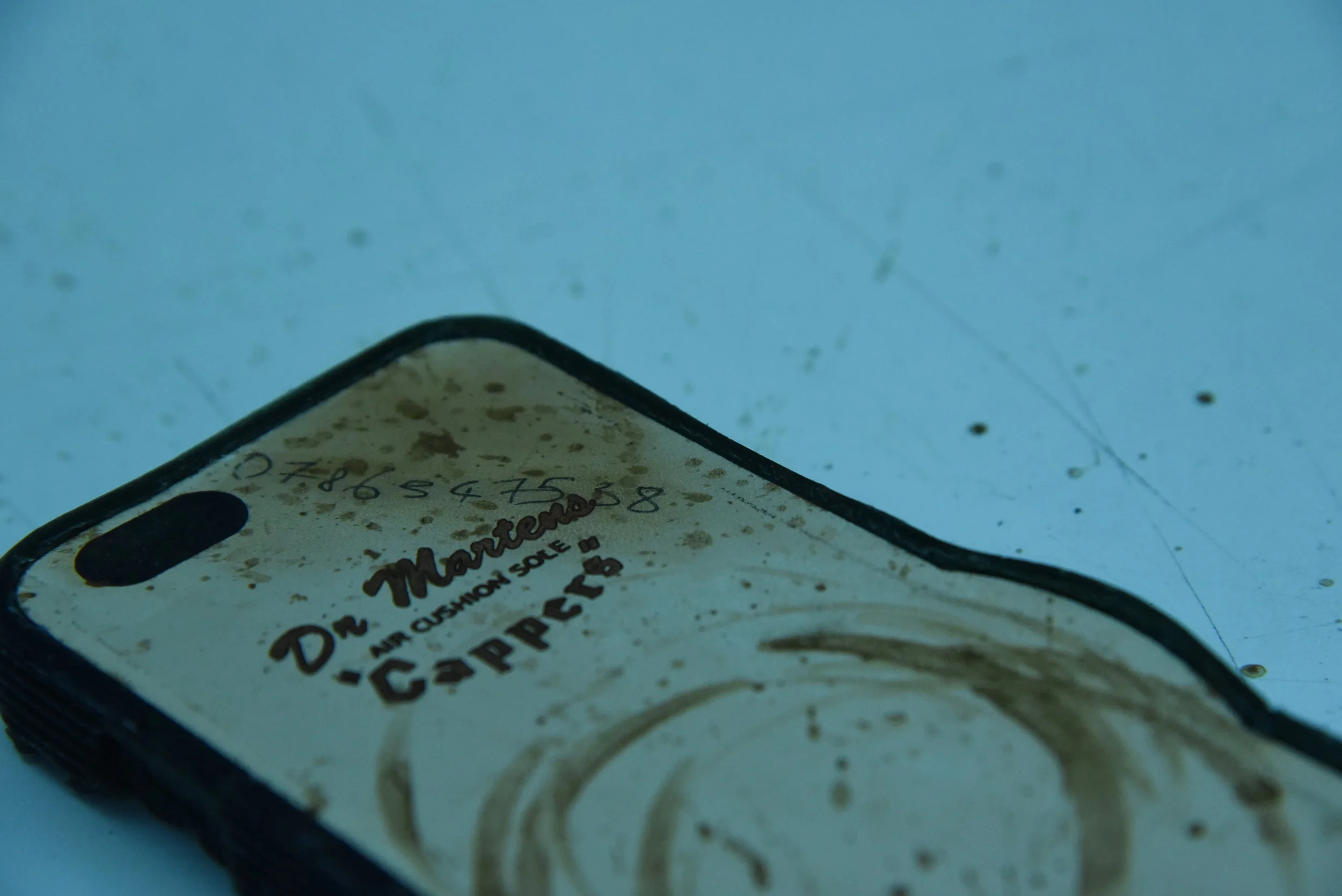

For the final phase, we worked on the Dr. Marten Phonecase. The concept behind the case is that you smash your phone down on the table and place a drink on top of it because you aren't a slave to your phone or technology. The concept embraces the rebellious youth spirit of Dr. Marten's generations of users. The shoe like treads on the front of the case is styled like the classic Dr. Marten airsole, encouraging the user to smash their phone down as if they were stomping their foot on the ground and the circular edge prompts a drink to be placed on top. The raw, untanned leather on the back will wear as it is used and can be personalized with ink, akin to customizing your own Dr. Marten boot. The tough rubber and vintage logo harkens back to Dr. Marten's origins as a rugged workwear brand.

The form and style of the case went through several iterations, at first containing many elements of the Dr. Marten boot such as the signature yellow stitching and bootstrap. These were later scrapped in favor of a less literal interpretation of the Dr. Marten boot while keeping the core brand values.

The manufacturing process involved creating one-part silicone molds from a 3D printed model. Meanwhile, the leather was laser cut into shape and laser etched with the vintage Dr. Marten 'Cappers' logo. The leather backs were centered and placed directly onto the rubber while casting for a permanent bond.

Team Members

- Arthur Gouillart

- Dongyuan Li

- Ahlad Reddy

- Hazel Yan